Learn About the Professional Car Maintenance Checklist

Outline:

– Why a Professional Checklist Matters

– Fluids and Filters: The Lifeblood of Reliability

– Tires, Brakes, and Suspension: Grip, Stop, and Stability

– Battery, Charging, and Electrical Health

– Belts, Hoses, Cooling, HVAC, and Seasonal Planning

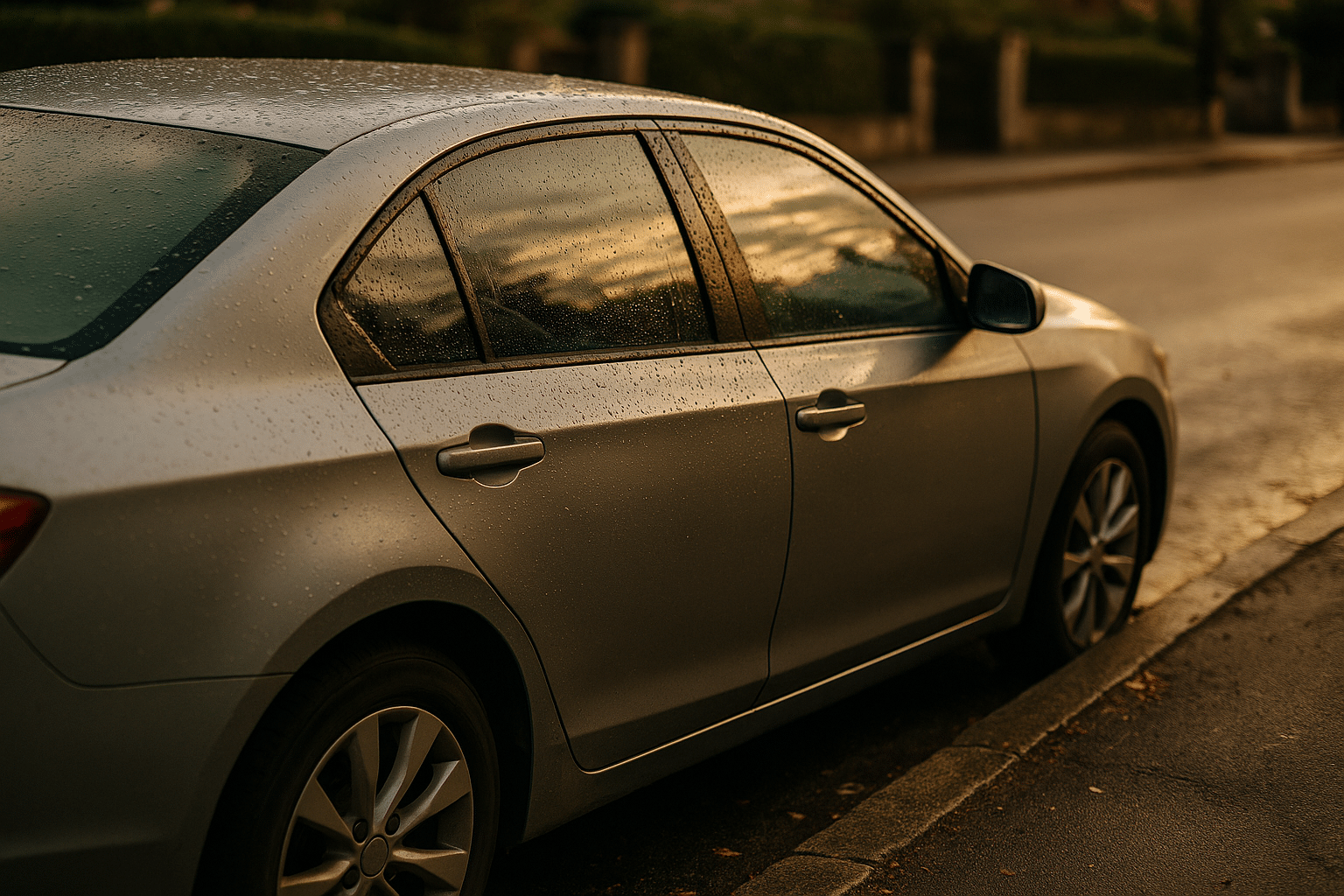

Why a Professional Checklist Matters

A well-kept vehicle isn’t just cleaner—it’s safer, more efficient, and less likely to leave you stranded. Professionals rely on checklists because they remove guesswork, standardize inspections, and ensure nothing essential gets skipped. Drivers benefit from the same discipline. A clear maintenance plan helps you spot minor issues before they snowball into costly repairs, and it anchors your decisions in intervals, specifications, and observable measurements rather than hunches. Think of it like a pilot’s preflight: routine, thorough, and quietly vital.

There are three big reasons to embrace a structured checklist. First, safety. Brakes, tires, steering, and lighting are frontline systems where early detection matters; catching uneven pad wear or low tread depth during an inspection prevents risky surprises on the road. Second, cost control. Replacing a $15 filter on time is far cheaper than repairing a damaged sensor or component downstream. Third, predictability. Scheduled checks—oil, coolant, battery, belts—build a cadence that reduces downtime and supports resale value with a tidy paper trail.

Data supports the practice. Underinflated tires can reduce fuel economy and raise heat buildup, accelerating wear and increasing stopping distances. Brake fluid absorbs moisture over time, lowering its boiling point and degrading pedal feel under heavy use. Batteries lose capacity as they age and with temperature swings; a quick voltage or conductance test can reveal a weak unit before winter exposes it. A professional-grade checklist puts these realities into a routine sequence: measure, compare with spec, document, and act.

To set expectations, a comprehensive maintenance pass typically includes: fluid levels and condition, filters and breathability, tire pressures and tread depth, brake thickness and rotor condition, suspension and steering play, battery and charging voltages, belts and hoses integrity, cooling performance, HVAC operation, wipers and lighting, plus seasonal prep. Each item doesn’t always require service—but each deserves a glance, a measurement, and a note. Over time, the notes tell a story of the car’s health and help you plan the next smart move.

Fluids and Filters: The Lifeblood of Reliability

Fluids carry heat, transmit force, lubricate surfaces, and keep contaminants at bay. Filters protect these fluids and your engine’s breathing from abrasive particles. Start with engine oil: check level on level ground, engine off, after a short wait so oil drains back. Color alone isn’t definitive, but gritty texture or a burnt smell is a warning sign. Change intervals vary by oil type and driving conditions; short trips, extreme temperatures, frequent idling, and towing all count as “severe” duty and justify shorter intervals. Always use the viscosity grade specified in your owner’s documentation, and replace the drain washer if required to prevent slow leaks.

Coolant stabilizes temperature and protects against corrosion. A 50/50 mixture of antifreeze and water typically guards down to around -34°F (-37°C), but concentration should be confirmed with a refractometer or test strips. Inspect the coolant reservoir level when cold, and look for discoloration, rust flakes, or oil sheen—none belongs there. Pressure-testing the system can expose leaks at hose connections, the radiator, or the water pump weep hole. Replace coolant on schedule to replenish corrosion inhibitors, and bleed air pockets after service to prevent hot spots.

Hydraulic brake fluid is hygroscopic, absorbing moisture that lowers its boiling point over time. Spongy feel after repeated stops, dark coloration, or a service interval reminder indicates attention is due. Flushing restores firm pedal response and helps prevent internal corrosion in lines and calipers. Power steering (where applicable) and transmission fluids each have distinct color and odor profiles when healthy; slipping, shuddering, or noise during turns often flags low level or contamination.

Don’t overlook filters. The engine air filter keeps abrasive dust from entering cylinders; a quick backlight test (hold it toward a light source) can reveal clogging. The cabin filter preserves HVAC efficiency and keeps interior air clean; a musty smell or weak airflow points to a replacement. Fuel filters protect injectors; service intervals vary but are critical for clean atomization and smooth starts.

Useful checkpoints:

– Engine oil: level, viscosity grade, interval, leaks around the pan and plug

– Coolant: level, freeze protection, discoloration, hoses firmness, radiator cap seal

– Brake fluid: level, color, service age, moisture content test if available

– Transmission/differential: level (if serviceable), color, odor, shift quality

– Filters: engine air, cabin, fuel—inspect, replace, and note date/mileage

Tires, Brakes, and Suspension: Grip, Stop, and Stability

Your tires translate every command into motion. Start with cold pressures, set to the placard in the driver’s door jamb; pressures typically change about 1 psi for every 10°F shift in ambient temperature. Check monthly and before trips. Measure tread depth across inner, center, and outer grooves; uneven wear suggests alignment or inflation issues. As a rule of thumb, replace tires at 2/32 in (about 1.6 mm) legal minimum, with many drivers choosing earlier replacement for wet traction. Rotate tires at regular intervals to even out wear patterns, especially on front-heavy vehicles.

Brake inspections should be systematic. Front and rear pad thickness, rotor condition, and evenness of wear matter. Pads nearing 3 mm are close to retirement; glazing or taper wear hints at caliper slide or hardware issues. Rotors should be checked for scoring and measured against minimum thickness. Pulsation under light braking often points to rotor thickness variation or uneven deposits, not always warping. A fluid flush at prescribed intervals maintains pedal feel and reduces internal corrosion risk. When test-driving after service, perform controlled stops to bed pads per manufacturer guidance for consistent friction.

Suspension and steering keep the tire contact patch stable. Inspect shocks and struts for oil seepage, damaged boots, and mounting bushing wear. Excessive body float after bumps or nose-diving under braking suggests loss of damping. Check ball joints and tie-rod ends for play; even small amounts can degrade alignment and steering precision. Control arm and stabilizer bar bushings crack and harden with age, adding clunks over bumps and reducing composure in corners. Wheel bearings should rotate smoothly with minimal free play; humming that changes with speed or when turning marks a likely bearing issue.

Quick at-a-glance checkpoints:

– Tire pressures (cold), tread depth across the width, sidewall damage

– Brake pad thickness, rotor surface and thickness, even wear side-to-side

– Brake hoses for cracks, caliper slide freedom, hardware condition

– Shock/strut leakage, bushing integrity, ball joint and tie-rod play

– Alignment symptoms: car pulling, crooked steering wheel, feathered tread

Prioritize fixes that affect safety first—braking, steering, and tire integrity—then move to comfort items. The payoff is immediate: stable tracking, shorter stopping distances, and quieter, more predictable handling.

Battery, Charging, and Electrical Health

Electrical reliability starts with a sound battery and a stable charging system. A fully charged 12‑volt battery typically measures around 12.6 V at rest; about 12.2 V indicates roughly half charge, and below that you’re on borrowed time—especially in cold weather. With the engine running, alternator output usually falls between about 13.7 and 14.7 V at the terminals. Fluctuations outside this window, belt squeal, or dimming lights at idle are red flags. If available, a conductance or load test gives a faster, more nuanced picture of battery health than voltage alone.

Corrosion is a silent thief of voltage. Inspect terminals, clamps, and ground straps; a thin layer of oxidation can cause intermittent no-starts and sensor gremlins. Clean with the proper tools and protect with dielectric grease on external surfaces. Check cable strain relief and routing to prevent chafing. Many issues blamed on “electronics” trace back to simple voltage drop across tired connections.

Parasitic draw deserves attention when a battery repeatedly drains overnight. Modern vehicles typically rest around 20–50 mA after modules go to sleep. A reading notably higher signals something staying awake—glovebox light, aftermarket accessory, or a control unit not timing out. Using an ammeter and pulling fuses methodically can isolate the circuit. Always follow safe procedures to avoid spiking sensitive modules when reconnecting.

Lighting, signaling, and safety systems belong on every checklist. Verify all exterior bulbs, brake lights, reverse lights, and hazards. Inspect wiper operation and washer spray pattern; streaking blades compromise visibility and are quick to replace. Confirm horn function, defroster operation, and that warning lights on the cluster illuminate briefly at key-on as a self-test. For intermittent dashboard warnings, scan for diagnostic trouble codes with an OBD-II reader and note freeze-frame data when available; even if you’re not doing the repair yourself, those details help a technician pinpoint causes quickly.

Quick checks:

– Battery: age, rest voltage, terminal condition, secure mounting

– Charging: running voltage, belt condition/tension, alternator noise

– Grounds: clean connections, tight fasteners, no frayed straps

– Parasitic draw: stabilized sleep current, isolate circuit if high

– Visibility and alerts: bulbs, wipers, washers, horn, defrosters, cluster lamps

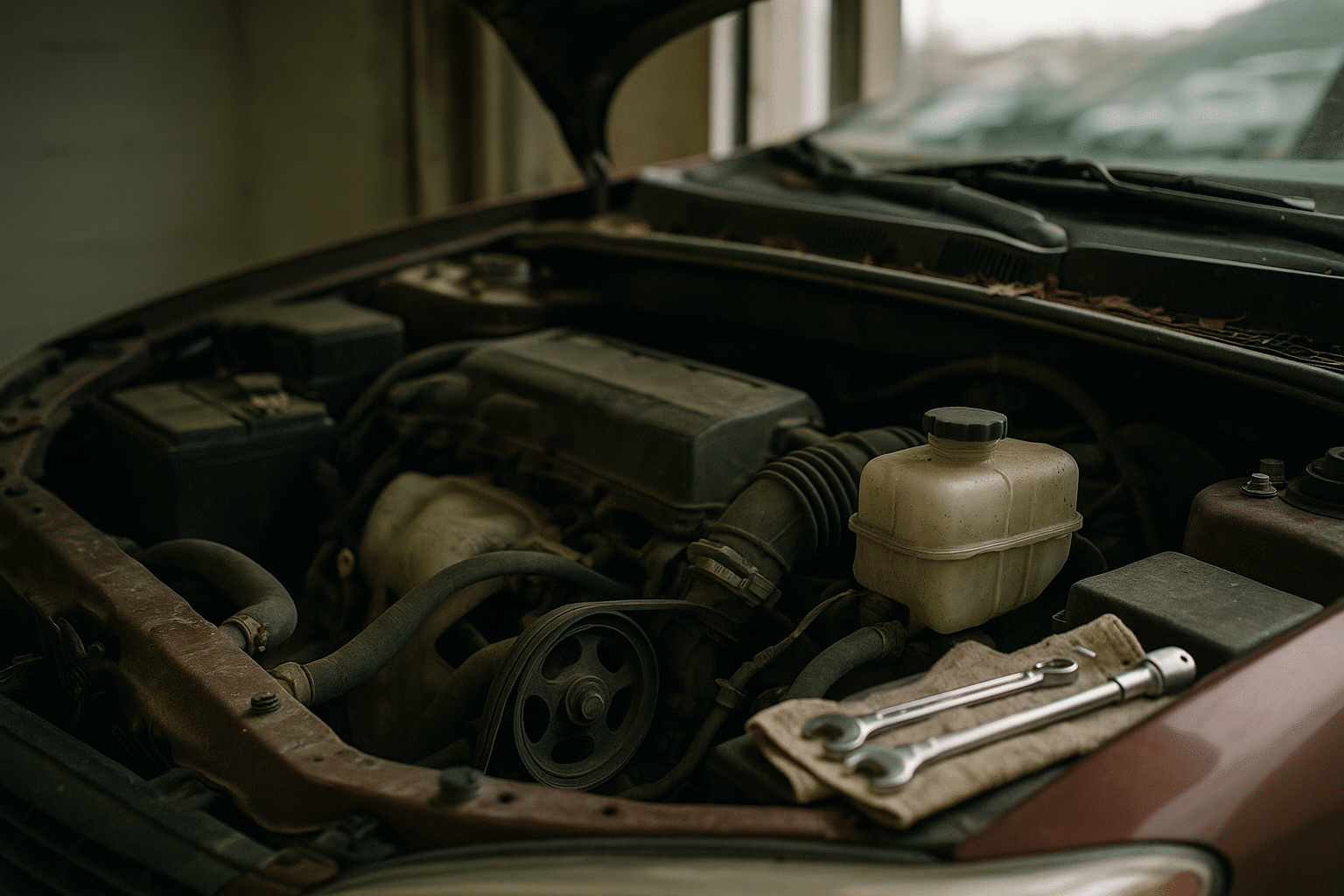

Belts, Hoses, Cooling, HVAC, and Seasonal Planning

Belts and hoses are the quiet workhorses tying systems together. A serpentine belt should track true with no frayed edges, chunking, or glazing. Micro-cracking on older designs signals age; chirps and slippage under load point to tensioner or pulley issues. Hoses should feel firm yet pliable—spongy or brittle spots, bulges near clamps, and coolant crust at joints are trouble signs. Replace any component that fails a visual or tactile check, and verify alignment after installation to prevent premature wear.

Cooling performance protects everything from head gaskets to transmission life (when a cooler runs through the radiator). Inspect radiator fins for debris and bent passages; gently straighten where accessible and clean from the engine side outward to avoid forcing debris deeper. A pressure test can reveal slow leaks, while a thermometer or scan tool watching coolant temperature and fan command helps verify thermostat and fan operation. After coolant service, confirm heater performance; weak heat can indicate air trapped in the system or a restricted core.

HVAC affects safety as much as comfort. A clean cabin filter preserves airflow and defogging speed. Use the defrost setting to ensure the compressor engages and the blend doors move as commanded; slow transitions or noises can indicate actuator wear. A simple vent-temperature check with a thermometer provides a baseline for A/C performance. If you suspect low refrigerant, avoid venting to the atmosphere and follow lawful handling procedures, or consult a licensed service provider for recovery and recharge.

Seasonal planning ties the whole checklist together. Before winter, test battery health, verify tire tread and pressures, check coolant freeze protection, replace worn wiper blades, and stock an emergency kit with a tire inflator, flashlight, and warm layers. Ahead of summer, confirm A/C function, inspect cooling fans, and clean condenser and radiator fins. For road trips, add a torque check on lug nuts, a look at spare-tire pressure, and a scan for stored codes.

Documentation is your silent ally. Record what you checked, measurements taken, and parts replaced with date and mileage. Over time, patterns emerge—slow coolant loss, a belt that chirps only in rain—that inform smarter decisions. The rhythm becomes second nature: a monthly quick check, quarterly deeper dive, and scheduled services based on time and miles. That’s the professional cadence—steady, thorough, and focused on preventing problems rather than chasing them.