Generator Installation: A Professional Guide to Backup Power Solutions

Outline:

– Assess loads and choose generator types

– Plan the site, permits, and code compliance

– Integrate transfer equipment and manage loads safely

– Select fuel, storage, and exhaust strategy

– Commission, maintain, and budget for lifecycle costs

Choosing the Right Generator: Loads, Types, and Realistic Sizing

Outages rarely send a calendar invite. They show up with wind, ice, or a grid hiccup, and the question becomes simple: what must stay on, and for how long? Before shopping for any machine, capture a clear picture of your essential loads and how they behave. Appliances have two power numbers: running watts and starting (surge) watts. A refrigerator that cruises at 150–300 W may need 600–1,200 W for a split second at compressor start. A well pump might draw 700–1,000 W running but surge to 2,000 W or more. Add lighting, a gas furnace blower (400–600 W), networking gear (30–60 W), and perhaps a small window AC or mini‑split. Tally running watts, then add starting surges for the largest motor that could start while others are on.

A practical essentials package for many homes lands around 3–6 kW, while broader coverage with central air, electric cooking, or a large heat pump can climb to 10–20 kW or more. Equipment output is affected by altitude and heat; a rough rule is to derate gasoline and propane engines by about 3% per 1,000 ft elevation and expect reduced output during hot spells. That matters when a summer storm knocks out power on a 95°F day and the air conditioner is the star of the show. Right‑sizing avoids two pitfalls: a unit that bogs at startup and one so oversized it runs inefficiently at a light load.

Consider generator families and their trade‑offs:

– Portable open‑frame: affordable, simple, flexible; louder, requires manual setup and refueling.

– Inverter portable: cleaner power for electronics, quieter; typically smaller output and higher cost per watt.

– Standby (fixed): automatic transfer, weather housing, runs on natural gas or propane; requires permits, pad, and pro installation.

Fuel influences both runtime and maintenance. Gasoline is available everywhere but ages quickly and oxidizes; propane stores well for years; natural gas, when available, offers continuous supply but depends on utility resilience; diesel provides long life and efficiency with disciplined fuel care. For scenario planning, sketch two columns: “must run” (refrigeration, heat source, sump pump, routers) and “nice to have” (range, clothes dryer, full‑house AC). Then apply diversity: not everything runs at once. With a modest load management plan, many households find that a 6–8 kW solution keeps life comfortable, while a carefully sized 12–18 kW standby can handle most circuits including moderate air‑conditioning—subject to local conditions, appliance mix, and code‑approved design.

Site Planning, Permits, and Codes: From Paperwork to Pad

Before a wrench turns, the project lives on paper. Most jurisdictions require one or more permits—electrical for the wiring and transfer equipment, building for the pad or anchoring, and fuel‑gas or mechanical for piping and venting. Plan review protects you and your neighbors: inspectors verify clearances, conductor sizing, overcurrent protection, and shutoff access. Expect a site visit before or after the pour and a final inspection after commissioning. Homeowner associations may also request a submittal with a location sketch and a noise statement.

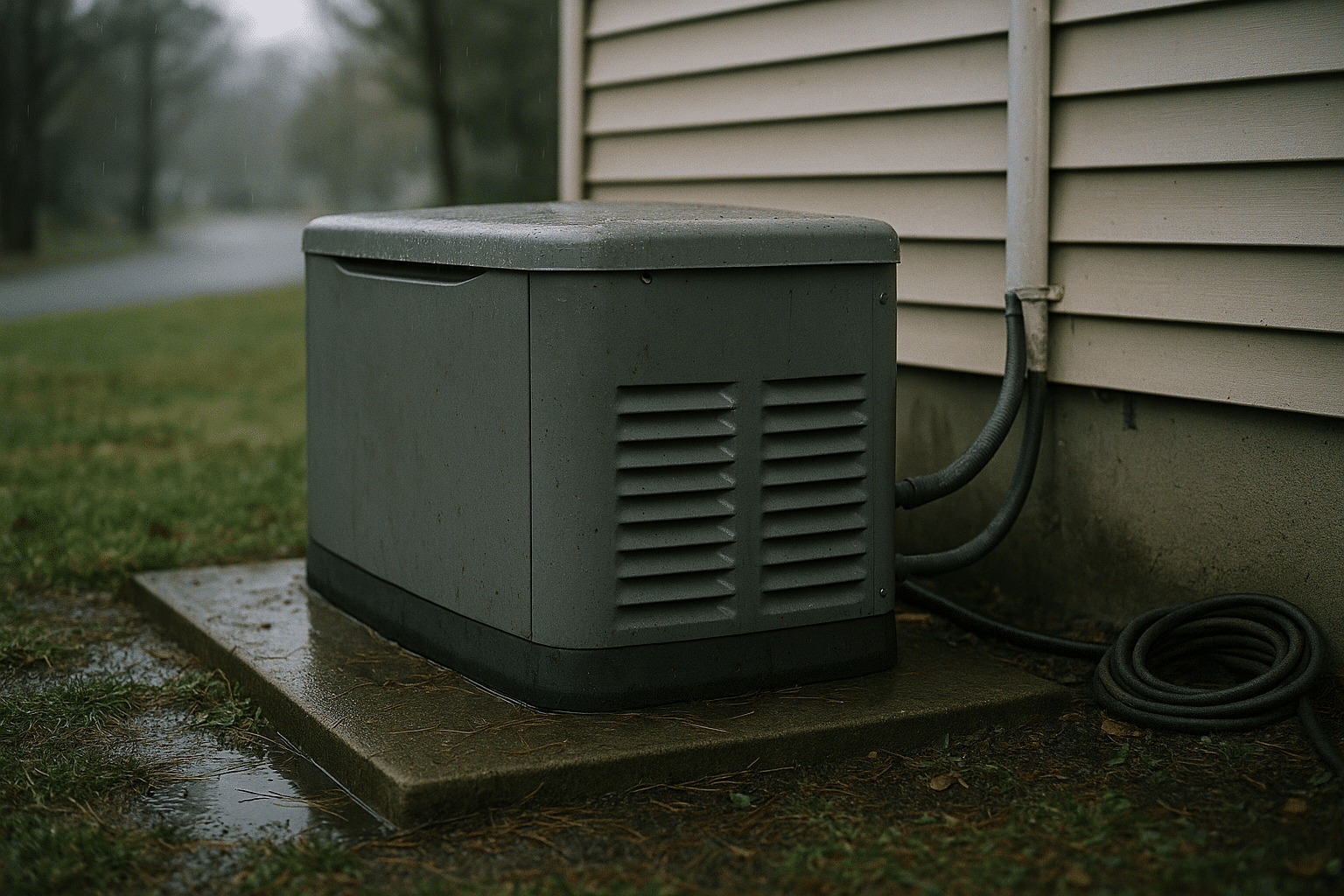

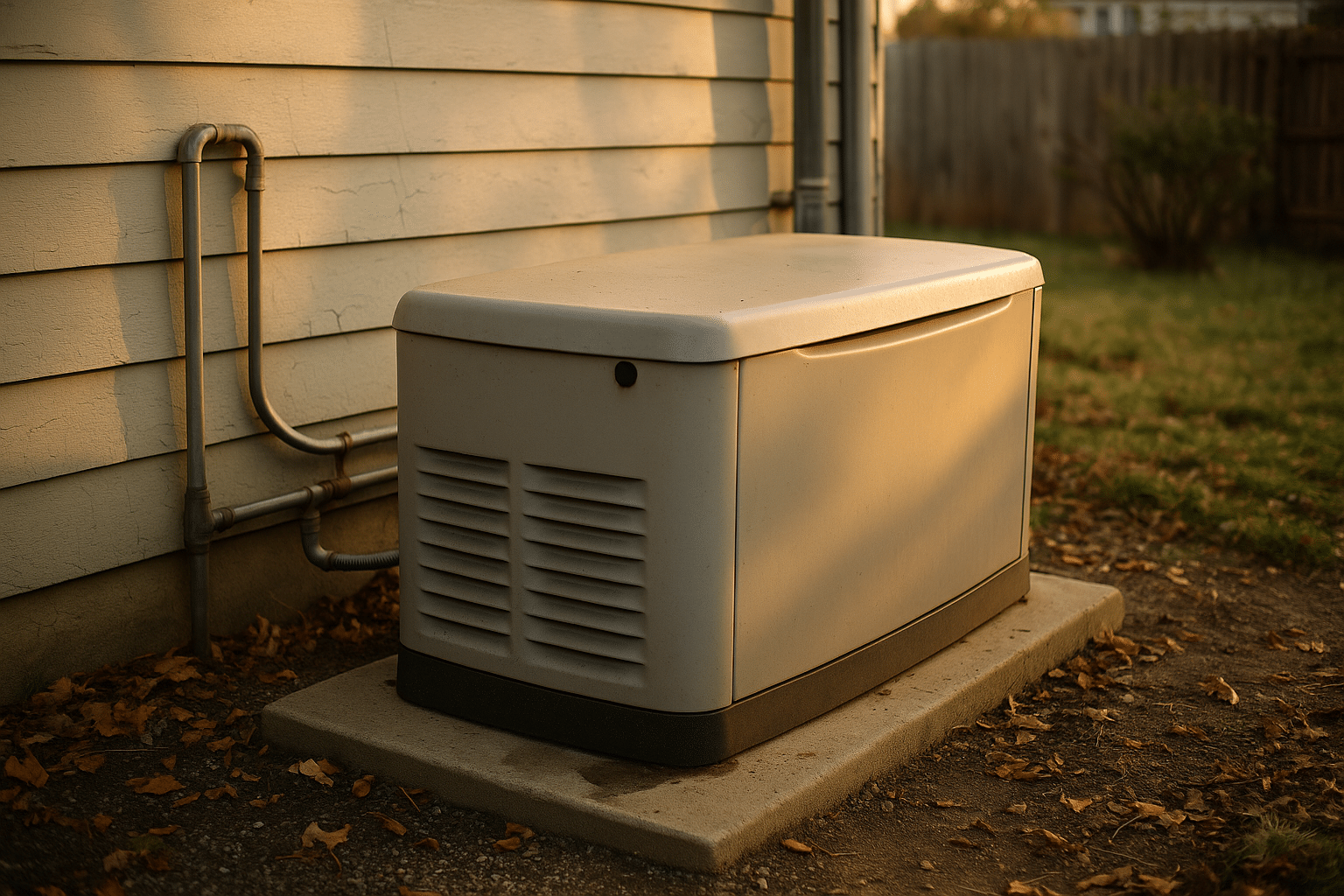

Placement shapes safety, noise, and serviceability. Keep the unit on a level pad above grade, not in a flood‑prone low spot or tucked into an alcove that traps exhaust. Maintain code‑required clearance from openings and ignition sources, and leave room on all sides for maintenance—filter changes are easier when a service tech can reach every panel. Think about prevailing winds, roof overhangs, and windows; you want exhaust to drift away from occupied spaces. Noise ordinances commonly measure sound at the property line, often aiming for neighborhood‑friendly evenings. Manufacturers state sound levels at a fixed distance (commonly around 7 m), but landscaping, fences, and house geometry affect perceived loudness on your lot.

Ground conditions and anchoring matter. A poured concrete pad or engineered composite base resists frost heave and keeps the frame dry. In coastal or high‑wind regions, local rules may call for specific anchors or tie‑downs. Where snow is routine, elevate slightly and orient service panels away from drifting. Avoid placing the unit beneath roof valleys that shed rain directly onto the enclosure. For propane tanks, respect required separations from buildings and openings; for underground tanks, account for access for refill trucks and cathodic protection where required.

Documentation simplifies approvals and future service:

– A scaled sketch showing the generator, transfer equipment, gas line route, and electrical conduit path.

– Cut sheets noting dimensions, sound levels, and fuel consumption (for load calculations).

– Code notes: conductor sizes, breaker ratings, grounding method, and labeling plan.

– A maintenance access plan so inspectors see that service panels are reachable.

The payoff for careful planning is a system that works smoothly on day one and ages gracefully. Good siting reduces noise complaints, keeps exhaust moving in the right direction, and makes annual service a short visit rather than a wrestling match. Permits create a record that can ease insurance questions and boost resale confidence, because the next owner sees a project built to code rather than a mystery box on a slab.

Smart Electrical Integration: Transfer Switching, Neutral Strategy, and Safety

The heart of a safe installation is the transfer method—the controlled handshake between utility and generator. Three common approaches anchor most projects. A manual transfer switch feeds a dedicated emergency subpanel; you decide when to switch during an outage and which circuits live on that subpanel. An automatic transfer switch monitors utility power and moves the load to the generator when the grid drops, then back again after a stable return. A listed interlock kit at the main panel can be acceptable where permitted: a sliding or bolted mechanism prevents the main breaker and the generator backfeed breaker from being on at the same time. All three share a goal: prevent backfeeding the grid and ensure only one source energizes the system.

Neutral treatment separates tidy installs from puzzling ones. If the transfer switch switches only the hot legs, the generator’s neutral is solidly connected to the service neutral (non‑separately derived system); in that case, the neutral‑ground bond stays at the service equipment, and the generator neutral is not bonded to the frame. If the transfer switch is designed to switch the neutral as well, the generator may become a separately derived system during operation; the neutral‑ground bond then occurs on the generator or within the transfer equipment per listing, and grounding electrode connections follow that scheme. Getting this wrong invites nuisance trips from GFCI/AFCI devices or, worse, unsafe touch voltages.

Wire sizing, overcurrent protection, and labeling are the next guardrails. Conductors must be sized for generator output and distance, accounting for voltage drop on longer runs. The generator feeder needs an overcurrent device within the listing’s instructions, and the equipment grounding conductor must be continuous and appropriately sized. Labels should be permanent and legible: “Emergency circuits,” “Generator inlet,” “Standby source disconnect,” and “Do not backfeed—utility workers at risk.” A simple laminated one‑line diagram on the inside of the panel door helps the next electrician—and you at 2 a.m.—see how energy flows.

A few practical safety notes:

– Never use a cord with two male ends to backfeed a dryer receptacle. It’s dangerous and violates code.

– Use a listed power inlet, correct twist‑lock connector, and wiring method rated for the environment.

– Keep neutrals and grounds separate in subpanels to avoid parallel neutral paths.

– Test transfer operation under controlled conditions before the first storm season.

Finally, consider load management. Soft‑start kits for compressors, priority load modules, or simple discipline (don’t run the oven and well pump at the same time) can trim generator size and cost without sacrificing comfort. When an automatic transfer switch includes load shedding, heavy hitters like central air can be staged intelligently, letting a modestly sized generator carry a home that would otherwise demand a much larger unit.

Fuel, Storage, and Exhaust: What Powers You When the Grid Doesn’t

Fuel choice sets the tone for runtime, upkeep, and logistics. Gasoline is widely available but ages in months without stabilizer; it absorbs moisture and can varnish carburetors. Propane stores cleanly for years in properly maintained cylinders or tanks; it burns clean, leaving less carbon in the engine. Natural gas offers convenience and long runtimes where the utility stays up; when lines are disrupted, however, it shares the grid’s vulnerability. Diesel delivers efficient torque and sips fuel at low RPM, but it asks for disciplined storage practices to prevent microbial growth and maintain cetane quality.

Consumption figures help with budgeting and tank sizing. As a ballpark, a mid‑size portable (around 5–7 kW) might use roughly 0.5–0.8 gallons of gasoline per hour at 50% load. A residential standby around 14–20 kW on propane might consume about 1.5–3.0 gallons per hour at half load, whereas natural gas use might be in the range of 120–230 cubic feet per hour for similar output. Diesel sets often hover near 0.4–0.7 gallons per kWh produced, depending on load factor and engine speed. Actual numbers vary by model, altitude, and temperature, so always consult the equipment data plate and plan for worst‑case loads.

Storage and piping deserve a checklist:

– Gasoline: use approved containers, store in a detached shed if possible, rotate every 3–6 months, and add stabilizer if cycling is infrequent.

– Propane: maintain required separations from buildings and ignition sources; anchor cylinders to prevent tipping; protect regulators from roof runoff and snow.

– Natural gas: size the pipe for flow and pressure drop; long runs or multiple appliances may require upsizing and dedicated regulators; perform leak checks with approved methods.

– Diesel: keep tanks clean, use biocide if recommended, and sample fuel annually; water separators and regular filter changes are your friends.

Exhaust is invisible until it isn’t. Carbon monoxide must never accumulate near sleeping areas, crawlspace vents, or soffits that feed attic air. Place the exhaust outlet downwind of common openings and maintain clear skies around the muffler. Never build walls, boxes, or planter enclosures that restrict airflow—even well‑intentioned noise fences can cause overheating if not engineered with proper spacing and vents. Indoors, use CO alarms on every level and near bedrooms; test monthly and replace units per manufacturer guidance.

Noise and vibration can be tamed without compromising safety. Orient the enclosure so its quiet side faces neighbors, place the pad on a firm base, and consider a gravel perimeter that absorbs splash and prevents mud. Strategic landscaping—evergreens, berms, and fences placed outside the required clearance zone—diffuses sound without sealing the unit into a tight cavity. A thoughtful fuel and exhaust plan cushions you from long outages and keeps the system welcome in your neighborhood, rain or shine.

Commissioning, Maintenance, and Costs: A Practical Path to Long‑Term Reliability

Commissioning is where drawings meet reality. Begin with pre‑start checks: verify oil, coolant (if liquid‑cooled), and fuel; confirm conductor terminations are torqued to spec; inspect bonding, grounding, and labeling. With the utility present and the main still on, confirm the generator starts, holds steady voltage, and sits at the correct frequency—60 Hz in many regions—under no load. Then simulate an outage. Watch transfer timing, listen for odd vibrations, and measure voltage at key circuits under actual load. An essentials panel might register a modest 2–4% voltage drop when a fridge starts; that’s normal if it recovers quickly. Finally, rehearse the return to utility power and verify the generator cool‑down.

Maintenance rhythms keep engines ready. Many portables ask for an oil change after the first 5–10 hours (break‑in), then every 50–100 hours or annually. Standby units often specify longer intervals—commonly around 100–200 hours or annually—with periodic filter changes. Exercise runs help: a 10–20 minute run monthly under a small load circulates oil, keeps bearings happy, and reveals early leaks. Batteries deserve attention too; float chargers maintain readiness, but batteries age and often need replacement every 3–5 years. Air filters, spark plugs, and valve checks (where applicable) round out the routine. If the system rarely sees heavy load, consider an annual or biannual load‑bank test to ensure voltage regulation and temperature control behave under real demand.

Lifecycle costs are broader than the sticker. A small portable might involve a modest upfront outlay plus fuel, oil, and the purchase of safe storage containers. A whole‑home standby solution layers equipment with installation: pad and trenching, gas work, transfer gear, permits, and inspections. Operating costs hinge on fuel price and load. As an illustrative example, if a propane standby consumes about 2 gallons per hour while supplying roughly 10 kW, and propane costs $2.50 per gallon, energy lands near $0.50 per kWh, ignoring maintenance; natural gas may be lower per kWh in many markets, while diesel varies with local pricing and duty cycle. Ongoing service—annual oil, filters, battery, and occasional repairs—adds predictably to the budget.

For homeowners and small facilities, the most efficient path is methodical: define critical circuits, set a fuel strategy that matches local realities, build a clean transfer solution, and plan for maintenance the way you plan for winter tires or roof checks. Do that, and the generator fades into the background—quiet, compliant, and ready. When the sky turns that particular shade of storm gray, you won’t be guessing. You’ll flip a switch—or the switch will flip itself—and life will keep moving on schedule. That is the real value of a professional backup power plan: calm, not drama; numbers, not luck; resilience, not noise.