Garage Door Repair: System Troubleshooting and Repair Guide

Outline:

– Section 1: Introduction, safety essentials, and core tools

– Section 2: Diagnostic workflow and symptom-based troubleshooting

– Section 3: Mechanical repairs for tracks, rollers, springs, and seals

– Section 4: Electrical and control issues, sensors, and remotes

– Section 5: Preventive maintenance plan and conclusion

Introduction, Safety Essentials, and Core Tools

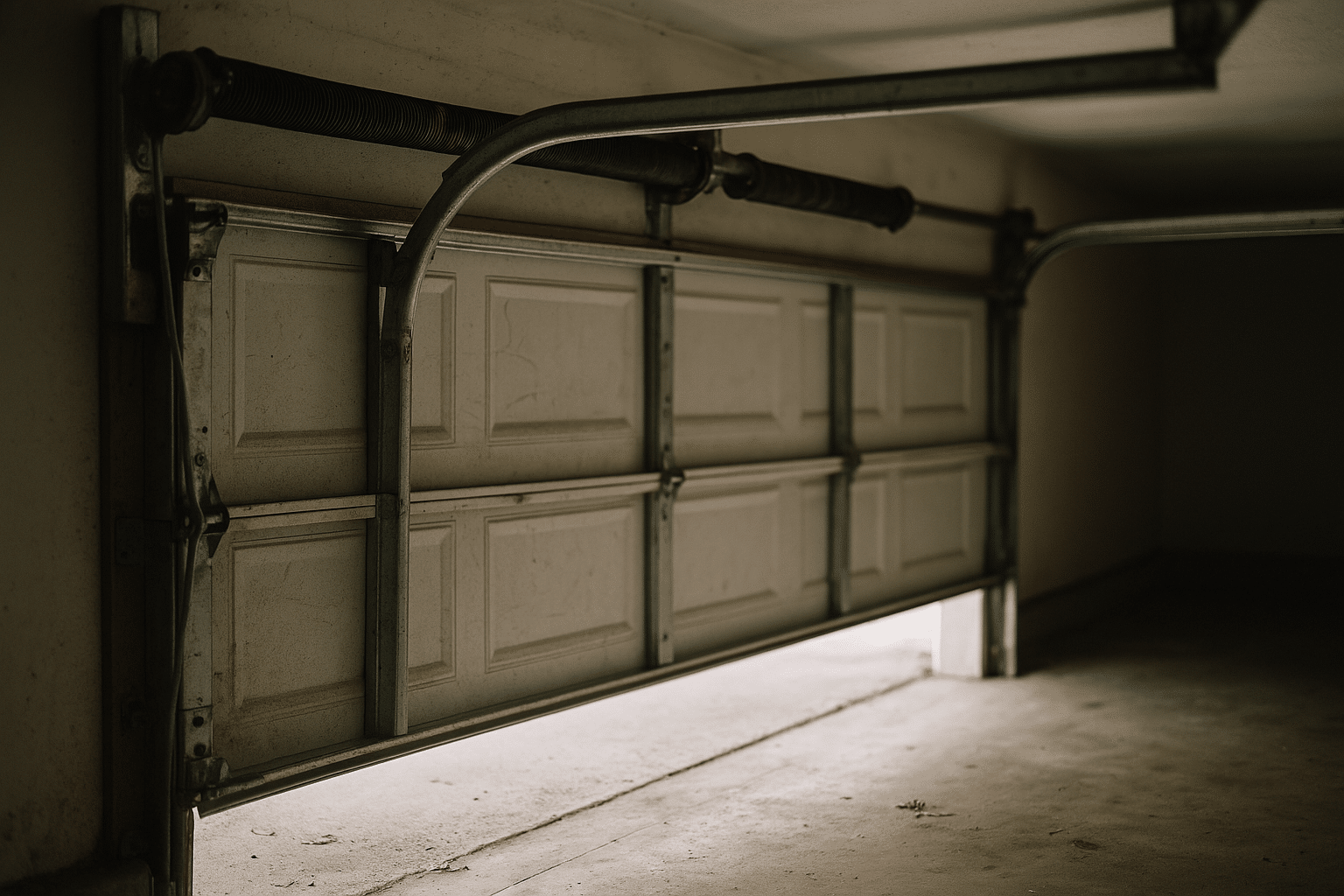

When a garage door misbehaves, it rarely whispers; it clanks, shudders, or stops mid‑stride like a tired marathoner. Because garage doors can weigh roughly 100–400 pounds depending on size and material, troubleshooting deserves a calm, methodical approach that puts safety first. Start by disconnecting power to the opener and, if applicable, engaging the manual release cord only when the door is fully down to avoid sudden movement. Torsion springs store significant energy, and uncontrolled release can cause severe injury; if you suspect a spring issue, pause and consider professional help before proceeding. A balanced, properly maintained door protects your household and reduces wear on the opener, saving money over the long run.

Before diving in, assemble a basic kit so you avoid repeated trips and risky improvisation. Helpful gear includes:

– A sturdy ladder, protective eyewear, and gloves for handling metal edges

– A flashlight or headlamp for inspecting tracks, drums, and cables

– A tape measure, level, and 7/16–9/16 inch wrenches for standard hardware

– Silicone‑based garage door lubricant (not penetrating oil) for rollers and hinges

– Mild cleaner and rags for tracks and photo‑eyes

– A multimeter and spare batteries for remote and keypad checks

Safety steps that reduce risk and confusion:

– Unplug the opener or switch off the circuit before any hands‑on work

– Use locking pliers on the track to prevent door travel during inspections

– Never loosen torsion spring set screws without proper bars and training

– Keep bystanders and pets clear until testing is complete

A quick orientation helps you read symptoms effectively. The door system is a partnership between mechanical parts (panels, hinges, rollers, tracks, torsion or extension springs, cables, drums) and the opener assembly (motor, gear train, logic board, limit/force settings, and safety sensors). Mechanical balance determines how hard the opener must work; if the door drifts up or down after disconnecting the opener, it’s out of balance and needs spring adjustment. Electrical controls decide when and how the door moves; dirty photo‑eyes, weak batteries, or mis‑set limits can mimic mechanical failure. With the right mindset, you can separate the two, measure small improvements, and move confidently from symptom to solution.

Diagnostic Workflow: From Symptom to Root Cause

Effective troubleshooting follows a simple rule: test the door manually before testing the opener. Pull the emergency release (with the door fully closed) to put the system in manual mode. Lift the door smoothly to waist height and release. If it stays put, balance is acceptable; if it slides down or rockets upward, spring tension is off, and the opener will struggle or stop. Track alignment matters too—sight down each vertical and horizontal section. Minor deviations of more than about 1/8–1/4 inch can bind rollers, leading to jerky travel and unusual noise.

Let the symptoms guide your sequence:

– Door won’t move at all: Check for locked manual slide on the wall button, tripped circuit, or engaged trolley release

– Door moves a few inches and reverses: Suspect photo‑eye obstruction, misalignment, or force/limit settings

– Excessive noise: Look for dry rollers, loose hinge bolts, worn center bearing, or cable rubbing guides

– Door closes then pops open: Inspect for binding tracks, a snagging cable, or overly sensitive down‑force

– Remote works intermittently: Replace battery, check for interference, confirm antenna placement, and try from varying distances

Inspect with intention. Clean tracks with a dry cloth—avoid grease inside the tracks, which attracts grit. Tighten loose fasteners on hinges and track brackets, but do not over‑torque; snug and secure beats stripped threads. Examine cables at the drum and bottom brackets; frayed strands, rust blooms, or bird‑nesting signal replacement needs. Wheels should spin freely; flat‑spotted or wobbly rollers add rumble and drag. If a roller axle rides at an odd angle, the hinge may be bent.

Don’t forget the environment. Cold weather thickens lubricants and stiffens rubber seals, increasing drag. Heat can expand metal, changing clearances. Wind can nudge a marginally aligned door into the safety envelope, causing an auto‑reverse. If the system behaves at noon but not at dawn, temperature may be a hidden variable. Write quick notes as you go—small observations like “binds near top panel on close” help you target exact components and avoid replacing parts without cause.

Finish the diagnostic pass by reconnecting the opener and running a full cycle with eyes on the door. Listen for where the sound peaks and watch for wobble or hesitation. If the door passes manual tests but fails when powered, shift your focus to controls, limits, force settings, and sensor signaling. If it fails both manual and powered tests, the path leads back to mechanical balance, track geometry, or hardware wear.

Mechanical Repairs: Tracks, Rollers, Springs, Cables, and Seals

Mechanical work starts with stabilizing the door. Clamp locking pliers below a roller on each side to prevent movement, and keep hands clear of the lift cables. Begin at the edges where issues often arise. Tracks should be plumb and parallel; measure spacing from the door edge to the track at multiple points. Variations beyond roughly 1/4 inch can pinch rollers. Loosen the mounting bolts slightly, tap the track with a rubber mallet to adjust, then retighten while holding alignment with a level.

Rollers influence noise and glide. Nylon‑tired rollers generally run quieter than bare steel and require less frequent lubrication at the axle, not inside the track. Replace rollers that wobble, have flat spots, or seized bearings. To swap a roller, remove hinge bolts on one panel at a time and slide the stem out of the track cutout; support the panel to avoid stress on neighbors. Check hinges for cracks or elongation at the screw holes—fatigued hinges allow panels to flex, causing popping sounds on travel.

Springs and cables demand caution. Torsion springs above the header store considerable energy; winding and unwinding require correct bars, steady technique, and knowledge of turn counts based on door height and drum size. Many homeowners choose to hire this step, which is a prudent decision. Extension springs along the horizontal tracks are less compact but still hazardous; ensure safety cables run through each extension spring to prevent recoil if a spring fails. Indicators you’ve reached the professional boundary include:

– A broken torsion spring (visible gap) or slipped drum set screw

– Frayed cables near the bottom bracket or uneven cable tension side to side

– A door that rockets up or slams down when disconnected from the opener

– Bent or cracked shaft, center bearing play, or deformed end bearings

Weatherstripping and bottom seals affect performance more than many realize. A hardened or torn bottom seal can add drag, admit water, and invite pests. Replacing it is straightforward: slide out the old seal from the retainer, clean the channel, apply a silicone‑safe talc or mild soapy water, and feed in the new seal with equal overhang at both ends to accommodate shrinkage. Side and top stops should lightly touch the door face without pressing; too tight and they rub, too loose and you lose efficiency.

Cycle life matters for planning. Many springs are rated around 10,000 cycles—about 6–8 years for a door used four times daily. Heavy doors, frequent use, and harsh climates shorten that timeline. Upgraded hardware with higher cycle ratings can extend service intervals, but any change in spring spec must match door weight and drum configuration. After mechanical work, always perform a manual lift test. The door should feel consistently moderate through the stroke and hold mid‑travel; only then should you reconnect power and fine‑tune the opener.

Electrical and Control Systems: Openers, Limits, Sensors, and Remotes

Once the door glides well by hand, the opener should only guide and control. Start with power basics. Verify the outlet is live; if dead, check the breaker and any nearby GFCI, often shared with garage or exterior outlets. Inspect the opener’s plug and cord for damage. If the wall control is unresponsive, remove it from the bracket, check low‑voltage wires for corrosion or loose screws, and confirm cable sheathing isn’t nicked along the route. Simple issues here can mimic more serious faults.

Limit and force settings determine how far and how firmly the opener moves the door. If the door stops short of closed or reopens immediately, the down‑limit may be set too conservatively. Adjust in small increments, test, and observe. If the door meets the floor, compresses slightly, and then reverses, reduce down‑force or correct mechanical binding. Aim for smooth contact without crush. For upward travel, set the up‑limit to stop when the top roller just clears the curved track; going too high can hammer the stops and stress hinges.

Photo‑eyes are the system’s sentinels. Mounted roughly 4–6 inches above the floor and facing each other, they must align so the invisible beam is uninterrupted. Clean the lenses with a soft cloth and confirm the brackets are not bent. Many sensors show a steady indicator when aligned and a flicker or dark state when misaligned; take note of your specific indicators. Typical causes of false trips include sunlight at a low angle, leaves moving across the beam, or a trash can nudging a bracket. Shielding the receiver side from glare with a small, non‑reflective visor can help in bright conditions.

Intermittent remote behavior often points to batteries or interference. Replace coin‑cell batteries proactively; nominal voltage is about 3V, and performance can degrade well before they go flat. If range is poor, check the opener’s hanging antenna; it should be straight and unobstructed. Wi‑Fi and nearby electronics can contribute to noise; try operating with other devices temporarily unplugged to isolate a culprit. For keypads, reseat the cover, clean contacts, and reprogram codes if entries are ignored. When logic boards fail, symptoms include random operation, dead terminals, or persistent sensor faults despite alignment. Board diagnosis benefits from a multimeter and patience; confirm low‑voltage outputs, continuity to sensors, and stable AC supply before concluding replacement is warranted.

After adjustments, perform a full safety reversal test. Place a 1.5‑inch‑high object (such as a scrap of wood) on the floor under the door and close it. The door should contact the object and reverse within about two seconds. Perform a beam interruption test by passing a broom handle through the photo‑eye path; the door should stop and reverse immediately. These functional checks are quick, but they validate that your electrical and safety systems are doing their job.

Maintenance Calendar, Cost Awareness, and Final Guidance

A reliable garage door isn’t an accident; it’s the result of small, steady care. Build a simple schedule so issues are caught while they’re inexpensive and easy to fix. Think of this as preventive medicine for a machine that guards your home and shoulders daily workload.

Suggested rhythm:

– Monthly: Wipe tracks, test safety reversal, check photo‑eye alignment, listen for new noises during one full cycle

– Quarterly: Lubricate rollers, hinges, and bearings with a light, silicone‑based garage lubricant; tighten hinge and bracket bolts; clean the bottom seal and header area

– Twice yearly: Perform manual balance test, inspect cables and drums, verify limit/force settings after seasonal temperature swings, clean keypad and remote contacts

– Annually: Replace keypad and remote batteries, inspect weatherstripping, confirm track plumb and parallel, and document any hardware changes

Budgeting helps reduce surprises. Typical service calls vary by region, door size, and parts, but a tune‑up is often a modest expense compared with emergency repairs. Spring replacements and cable work require skill and carry higher risk; many homeowners choose professional service for these tasks. When evaluating quotes, look for clear descriptions of parts, cycle ratings, and warranty terms, and ask whether balancing and safety checks are included. A transparent scope prevents miscommunication and ensures the whole system—not just one component—returns to safe operation.

Know your limits and your goals. It’s reasonable for a careful homeowner to clean tracks, tighten hardware, lubricate moving parts, replace weather seals, swap remote batteries, adjust photo‑eyes, and tweak limits in small steps. It’s equally reasonable to call a trained technician for spring work, major cable issues, bent shafts, door re‑sectioning, or logic board failures. Watch for warning signs:

– Door won’t stay mid‑travel during manual test

– Cables are frayed or unevenly spooled on drums

– Torsion spring shows a gap or makes sharp ticking noises

– Panels are cracked, or hinges tear away under load

Closing thought: treat the garage door like the front door’s stronger, busier cousin. When you listen for new sounds, measure small misalignments, and schedule quick checkups, the door rewards you with smooth, drama‑free operation. Whether you’re tightening a loose hinge or planning a professional spring replacement, the approach in this guide helps you act with confidence, protect your time, and keep one of your home’s biggest moving systems working dependably day after day.