Comprehensive Garage Renovation Guide: A Full-Process Solution from Space Optimization to Functional Upgrades

Blueprint and Scope: Laying the Groundwork

Before the first screw, paint roller, or layout line, a successful garage renovation starts with clarity. Think of this space as a Swiss Army knife for your home: it can store seasonal gear, house a vehicle, host a workbench, and still have room for bikes or a fitness corner. The stakes are real—organized garages reclaim square footage you already own, reduce damage to belongings, and can support property value by improving curb appeal and functionality. To get there, you’ll need a plan that aligns goals, budget, and the realities of the structure. Begin with a walk-through and a tape measure, and don’t be shy about sketching a scaled layout; even a rough drawing helps test scenarios and avoid costly do-overs.

Outline for what follows:

– Assessment and goals: inventory, measurements, code checks, moisture and structure review

– Space planning: zones, clearances, vertical/overhead storage, workflow

– Surfaces and envelope: floors, walls, insulation, air sealing, fire separation

– Systems and safety: lighting, power, ventilation, heating/cooling, hazards

– Budget, permits, timeline, and upkeep: cost tiers, approvals, execution, maintenance

Start with a detailed inventory. Group items into keep, donate, recycle, and dispose. Note unusual demands: tall equipment, long lumber, or temperature-sensitive finishes. Measure floor area, ceiling height, the sweep of garage doors, and the footprint of a parked vehicle with doors open. Common clearances that prevent daily annoyance include about 36 inches of walkway around vehicles and enough vertical space to keep overhead racks clear of door tracks when open. Check for moisture issues (darkened concrete, salt deposits), damaged framing, termites, or rusted fasteners. A simple plastic-sheet test over a taped area of slab can reveal vapor concerns; fogging under the plastic over 24–48 hours suggests you should address moisture before applying coatings.

Codes matter. Garages typically require ground-fault protection for 15- and 20-amp receptacles, fire separation from living spaces, self-closing doors to the house, and safe venting for fuel-burning appliances. Local requirements vary, so verify before you buy materials. A reality check on desired outcomes helps, too. A tidy parking-and-storage upgrade can be done over a few weekends; a fully outfitted workshop with new circuits, insulation, and finishes is a deeper project. Write down the non-negotiables (for example, “one car must fit through winter” or “bench dust must not reach the laundry”), and let those drive decisions. Good planning is the quiet superpower behind a garage that works as hard as you do.

Space Optimization: Zoning, Storage, and Workflow Without Clutter

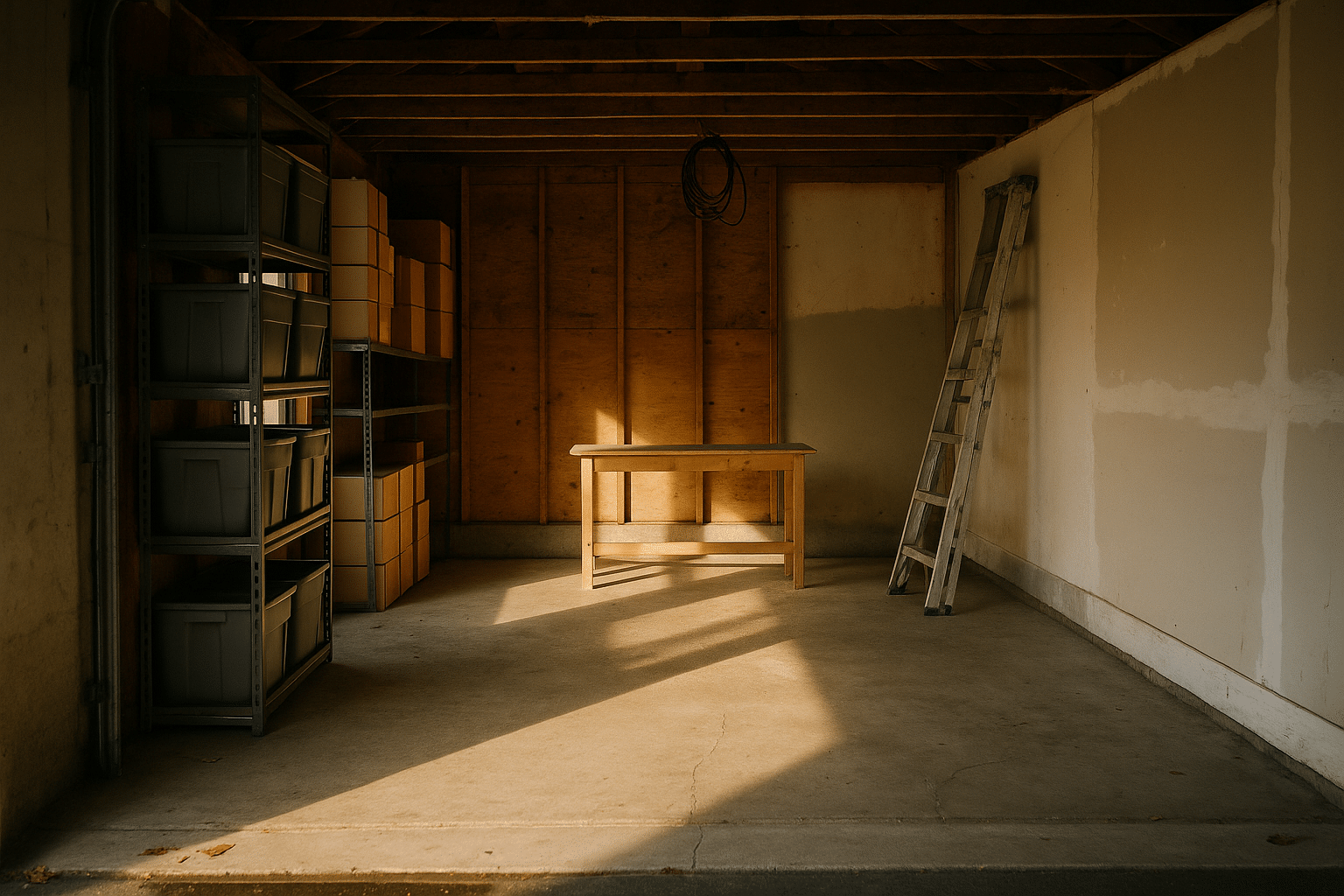

Great garages feel easy to navigate because their layout matches how you live. Split the footprint into clear zones: vehicle parking, deep storage, everyday grab-and-go, and a task area such as a bench or hobby corner. Start with the fixed elements—doors, windows, water heaters, steps—and design around them. Parking sets the backbone: a typical mid-size car needs roughly 14–16 feet of length and about 6–7 feet of width, but add room for door swing and walking paths. Aim to keep at least 24–36 inches free along side walls for shelves without scraping paint. For two vehicles, staggered parking or offset shelving near the rear wall can preserve comfortable aisles.

Vertical storage is your best ally. Open steel shelving is adaptable and cost-effective; closed cabinets hide visual clutter and add dust control; plywood-backed tool walls provide a robust mounting surface for hooks, bins, and cleats. Comparisons worth noting:

– Open shelves: fastest access; requires good bin discipline; excellent for labeled totes

– Closed cabinets: tidy appearance; protects from dust; slightly higher cost and depth

– Modular rails and cleats: reconfigurable; great for odd shapes; benefits from a solid backer

Overhead racks unlock cubic feet otherwise wasted. Typical ceiling-mounted platforms are rated from a few hundred to several hundred pounds, but always verify joist capacity and keep safe clearances from door tracks and openers. Use locking hardware, lag bolts into framing, and distribute loads evenly. Seasonal items—camping gear, holiday decor, luggage—belong up high. Everyday items—pet supplies, cleaning kits, frequently used tools—live between knee and eye level for minimal bending and ladder time.

A smart workflow reduces steps and prevents collisions between tasks. Place a shallow bench along a side wall closest to natural light if possible. Keep noisy or dusty work toward the garage door, where ventilation is easier. Corral small parts with divided bins; store paints and solvents in a ventilated, cool corner away from ignition sources. If you cycle or garden, mount racks near the door for quick fast exits. For sports gear, tall lockers keep balls and bats from rolling across the floor like runaway marbles. Finally, mark a “no storage” zone near the door tracks and opener arms to keep mechanics unobstructed. When everything has a place, the garage starts to feel less like a catchall and more like a tuned instrument.

Surfaces and Envelope: Floors, Walls, Insulation, and Durability

The concrete slab is the garage’s stage, and its performance affects everything you do on it. You have four mainstream floor strategies: leave concrete sealed, apply a two-part epoxy coating, choose a polyurea or polyaspartic system, or install interlocking tiles. Sealed concrete is budget-friendly and quick; it resists dusting and stains modestly. Epoxy offers richer color, chemical resistance, and a smoother cleanup but requires thorough prep—degreasing, grinding, and confirming moisture levels. Polyurea and polyaspartic systems cure faster and can be applied in wider temperature ranges, often with higher abrasion resistance; they cost more but shorten downtime. Interlocking tiles install over imperfect slabs and introduce texture underfoot; they’re convenient to replace piece by piece, though trapped moisture and dirt can build up underneath without periodic lift-and-clean cycles.

Preparation often determines success. Fill cracks with appropriate repair compounds, chase out loose edges, and address spalling. Many coatings need a concrete surface profile created by mechanical grinding. Moisture is a spoiler: high vapor emission can cause coating failure, so consider membranes or breathable options if tests suggest concerns. Also verify that your floor slopes slightly toward the garage door; roughly 1/8 inch per foot helps discourage puddles from wandering inward. A shallow trench or mat near the entry can capture meltwater in snowy climates.

Walls and ceilings deserve equal attention because the garage forms part of the home’s thermal and fire boundary. For attached garages, fire-rated gypsum board between the garage and living spaces is commonly required; ceilings beneath living areas often need thicker, fire-resistant panels. If you plan to hang heavy storage, a layer of plywood sheathing behind or over drywall creates a continuous fastening surface. Insulation choices depend on framing depth and climate. Typical 2×4 walls accept R-13/R-15 batts; 2×6 walls take R-19/R-21; ceilings can range from R-30 to R-49 or more. Add air sealing at the top plate, around outlets, and where the slab meets the wall. Weatherstrip the side door, install a threshold at the house entry, and maintain gaskets around the garage door to cut drafts and dust migration.

Finally, finishes. Light-colored, washable paint lifts the mood and reflects illumination; semi-gloss or satin is practical. In high-impact zones, consider a lower rail of tough paneling that shrugs off scuffs. A splash of accent color on the bench backsplash or storage panels gives subtle personality without overwhelming the calm. The result is a shell that’s tougher, cleaner, and quieter—one that feels thoughtful each time you swing the door up.

Power, Light, Air, and Safety: Systems That Make the Space Work

Outlets, lighting, air movement, and heat control determine whether your upgraded garage feels like a polished workspace or a dim cave. Start with electrical. Many projects benefit from a new 20-amp circuit for tools and separate circuits for lighting, door operators, and a refrigerator or freezer. GFCI protection is typically required for 15- and 20-amp receptacles in garages; local codes may also require arc-fault protection. If you plan a high-draw tool or an electric vehicle charger, consult an electrician about 240-volt circuits and panel capacity. Mount outlets at a comfortable height (for example, 42 inches above the floor at the bench) to reduce cord tangles. Keep cords off the floor path where vehicles roll.

Light transforms the garage more than almost any other upgrade. A common target for ambient lighting is around 20–30 lumens per square foot; tasks like woodworking or tuning call for 50–75 lumens per square foot over the work surface. For a 400-square-foot two-car garage, that means roughly 8,000–12,000 lumens of general light plus 4,000–6,000 lumens focused on the bench. Choose a neutral color temperature (around 4000–5000K) for clarity without harshness. Minimize shadows by distributing fixtures across the ceiling rather than concentrating them at the center. Supplement with under-shelf or under-cabinet strips at the bench and a movable light for fine work. Exterior motion-activated lights near the door help with safe entries after dark.

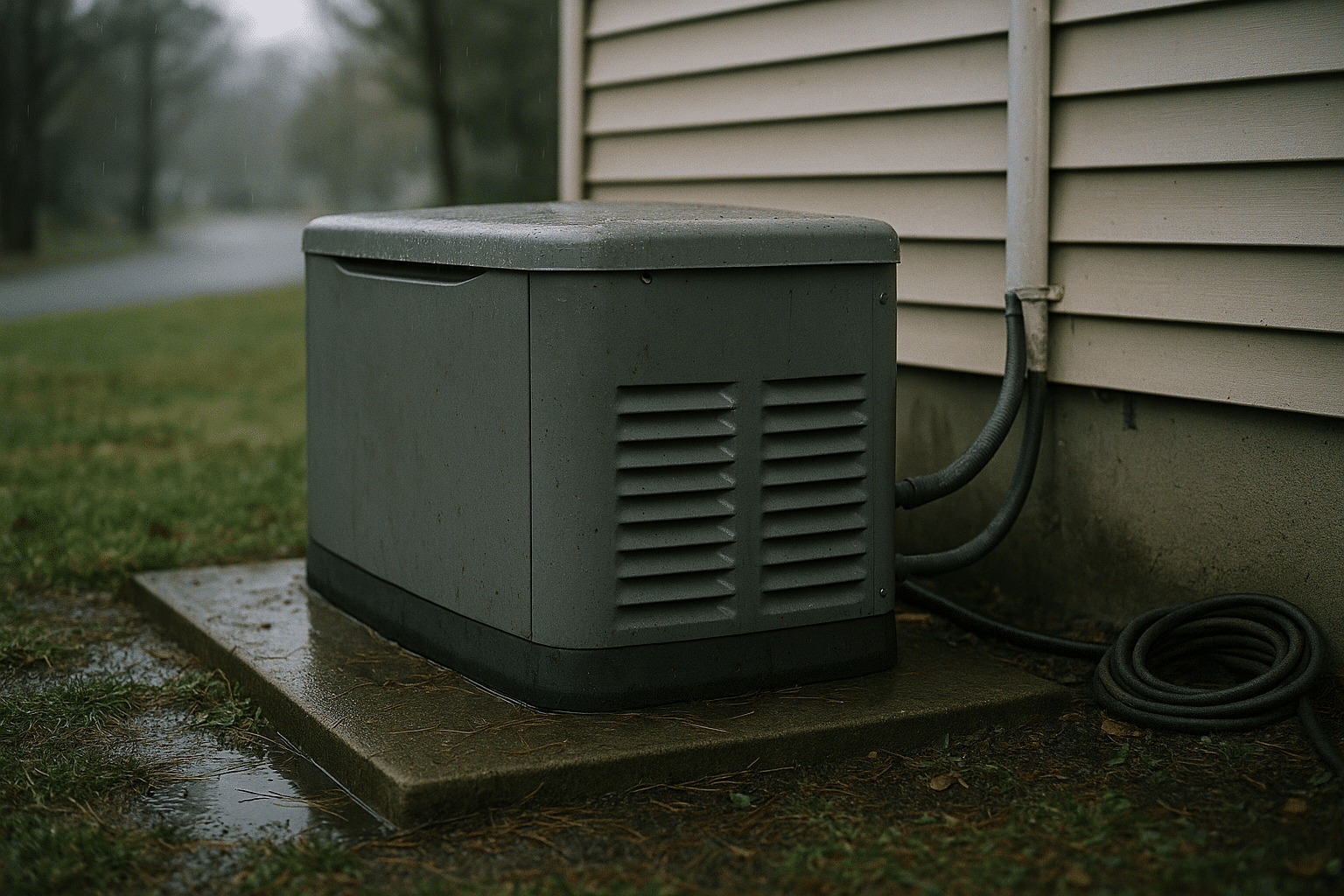

Ventilation and climate control protect tools and people. Aim for 6–10 air changes per hour when sanding or finishing. As a rough example, a 200-square-foot single bay with an 8-foot ceiling holds about 1,600 cubic feet of air; at 6 air changes, a fan delivering around 160 CFM maintains turnover. Place intakes low and exhaust high to sweep dust and fumes out. In humid regions, a dehumidifier set near 45–55% relative humidity curbs rust and mold. Heating or cooling options include radiant heaters (quiet, targeted warmth), forced-air units (quick heat, some noise), and ductless heat pumps (efficient year-round, higher upfront cost). Insulation, weatherstripping, and a door with adequate thermal performance reduce load regardless of the system.

Safety is the quiet hero of any upgrade. Keep flammables in a ventilated, metal cabinet away from ignition sources. Install a fire extinguisher rated for ordinary combustibles and flammable liquids near the exit, not buried deep inside. Add a carbon monoxide alarm near the door to the house and avoid running engines indoors. House-garage doors should self-close and seal well. Store heavy items low, secure tall cabinets to studs, and use lag screws for wall racks. A small spill berm or rugged mat near the parked car catches drips so they don’t wander under stored boxes. Safe choices don’t call attention to themselves; they simply let the rest of the garage shine.

Budget, Timeline, Permits, and the Final Word

Money and time shape the scope as much as ambition. Think in tiers:

– Refresh: deep clean, declutter, basic shelving, wall paint, and improved lighting; ballpark a few hundred to a few thousand

– Mid-range: overhead racks, workbench, upgraded circuits, modest insulation, and a durable floor coating; expect mid four figures to low five figures

– Comprehensive: reframe sections, extensive insulation, fire-rated assemblies, multi-circuit electrical, dedicated ventilation, and premium floor systems; ranges can reach into the tens of thousands

Timeline depends on complexity. A refresh can be accomplished over two or three weekends with planning. Mid-range projects often run 2–6 weeks depending on lead times and contractor availability. Comprehensive upgrades can span 1–3 months when permits, inspections, and weather are factors. Sequence tasks to avoid rework: demo and declutter; structural fixes; electrical rough-in; insulation and air sealing; drywall and finishes; floor prep and coating; storage install; final lighting tweaks and labeling.

Permits are not paperwork for paperwork’s sake; they protect safety and resale. Triggers commonly include new circuits, structural changes, new plumbing, changes to openings, and converting a garage to conditioned living space. Attached garages share boundaries with living areas, so fire separation and ventilation requirements often apply. Keep receipts and photos of work stages for future buyers and appraisers. Insurance carriers may also ask for evidence that heaters or fuel storage meet guidelines.

DIY versus hiring help is a spectrum, not a binary. You might handle decluttering, painting, and bolt-on storage while bringing in licensed pros for electrical, gas, or structural tasks. Decide based on risk, tool availability, and time. A practical rule: if a mistake could harm people or property, or if code requires inspection, call a professional.

Value often shows up beyond appraisals. Industry cost-versus-value studies frequently rank garage-related exterior improvements among projects with strong cost recovery, and organized storage prevents replacement purchases. More importantly, you gain hours of sanity each month. The conclusion is simple: start where you stand. Clear a corner, map your zones, and choose one surface or system to upgrade this season. With each pass, the room evolves from catchall to cornerstone—built for everyday life, ready for weekend projects, and resilient for the long haul.