Electric Vehicles: An In-Depth Look at Future Mobility Technologies

Why Electric Mobility Matters Right Now

Outline of this guide:

– Context and adoption trends, with a clear look at why electric mobility matters today

– Batteries and energy storage: chemistry, cost trajectories, and recycling

– Charging infrastructure, grid integration, and reliability in the real world

– Software-defined vehicles, driver assistance, and connected services

– Conclusion: practical next steps for drivers, fleets, and cities

Electric vehicles are no longer a novelty; they are becoming a mainstream tool for moving people and goods while reducing urban air pollution and tailpipe emissions. In several large markets, plug-in models have climbed from well under 5% of new sales a few years ago to roughly one in five today, with wide variation by region and segment. The appeal is a three-part story: cleaner urban air, lower running costs, and a quieter, more responsive driving experience. At the same time, there are realistic constraints: charging access can be uneven, mineral supply chains must scale responsibly, and grid operators need new tools to balance peaks. The point is not perfection but progress—measured, verifiable, and shared.

Consider costs. When electricity prices are moderate and fuel prices are high, total cost of ownership for an electric compact or midsize model typically undercuts a comparable combustion vehicle over three to five years. Electricity at home, especially on off-peak rates, can translate to roughly one-third to one-half the per‑mile energy cost of gasoline or diesel. Maintenance is often lighter because there are fewer moving parts, no oil changes, and reduced brake wear thanks to regenerative braking. Yet the purchase price remains higher in many regions, so incentives, fleet-scale procurement, and falling battery prices all play important roles in reaching parity.

From an environmental perspective, the benefits depend on how electricity is generated and how materials are sourced. Life-cycle analyses generally show lower cradle-to-grave greenhouse gas emissions for electric vehicles than for combustion models, even on grids with a meaningful share of fossil power, with the gap widening as grids add more renewables. Tailpipe emissions are zero, which materially improves local air quality in dense corridors. Responsible mining, strong labor standards, and rapidly improving recycling processes are central to making these gains stick.

In short, the electric shift is both a technology transition and a systems puzzle. The prize is not only cleaner transport but a mobility platform that can coordinate with homes, buildings, and the power system. The remainder of this article dives into the hardware and software under the skin, the charging ecosystem that supports it, and practical steps to navigate the change with confidence.

Batteries and Energy Storage: Chemistry, Cost Curves, and Breakthroughs

Modern electric vehicles rely on lithium-ion batteries engineered from families of materials that trade off energy density, cost, durability, safety, and supply risk. Two common cathode approaches illustrate the balance: iron‑phosphate emphasizes affordability, long cycle life, and thermal stability, while nickel‑rich chemistries push higher energy density for long‑range models and performance segments. Typical pack-level energy density spans roughly 130–180 Wh/kg for iron‑phosphate and 200–260 Wh/kg for nickel‑rich designs, with continuous improvements at the cell and pack integration level. Silicon‑enhanced anodes are emerging to raise energy density further, while careful thermal management maintains performance in heat and cold.

Cost trends remain decisive. Pack prices, once well above 1,000 USD/kWh, have declined by an order of magnitude over the past decade, with recent averages near the low hundreds at scale. Learning rates—cost reductions associated with doubling cumulative production—continue to apply as factories ramp, yields improve, and supply chains diversify. Near‑term headwinds like commodity spikes can offset progress for a season, but historical data shows a steady glide path toward sub‑100 USD/kWh at pack level as manufacturing expands and chemistries optimize materials intensity.

Next‑generation approaches matter, but timelines should be understood soberly. Solid‑state designs promise higher energy density and improved safety via solid electrolytes; however, their commercial rollout is expected in stages, starting with smaller packs or premium segments before broad adoption. Sodium‑ion cells are gaining momentum for affordable, short‑ to mid‑range vehicles and stationary storage thanks to reduced dependence on scarcer metals, albeit with lower energy density than mainstream lithium chemistries. Hybrid pack architectures, advanced cell formats, and cell‑to‑pack integration cut parts count and improve volumetric efficiency without waiting for entirely new chemistries.

Durability is often underestimated. A well‑managed pack can retain 70–85% of original capacity after 1,000–2,000 full‑cycle equivalents, depending on chemistry and use. Intelligent thermal control, conservative fast‑charging habits, and avoiding prolonged extremes of state of charge extend life. End‑of‑life is not the end of value: diagnostics can steer batteries into second‑life stationary use, and recycling is improving rapidly. Closed‑loop facilities can recover high shares of nickel, cobalt, copper, and aluminum, with lithium recovery rates rising. This reduces upstream mining pressure and locks in environmental gains.

For buyers comparing specifications, a few guidelines help:

– Range claims are estimates; temperature, speed, payload, and terrain can swing real‑world results by 20–40%

– Fast‑charge times depend on both peak power and the shape of the charging curve; a short plateau at high power often matters more than headline numbers

– Software plays a critical role in longevity; preconditioning before fast charging and smart charge limits pay dividends

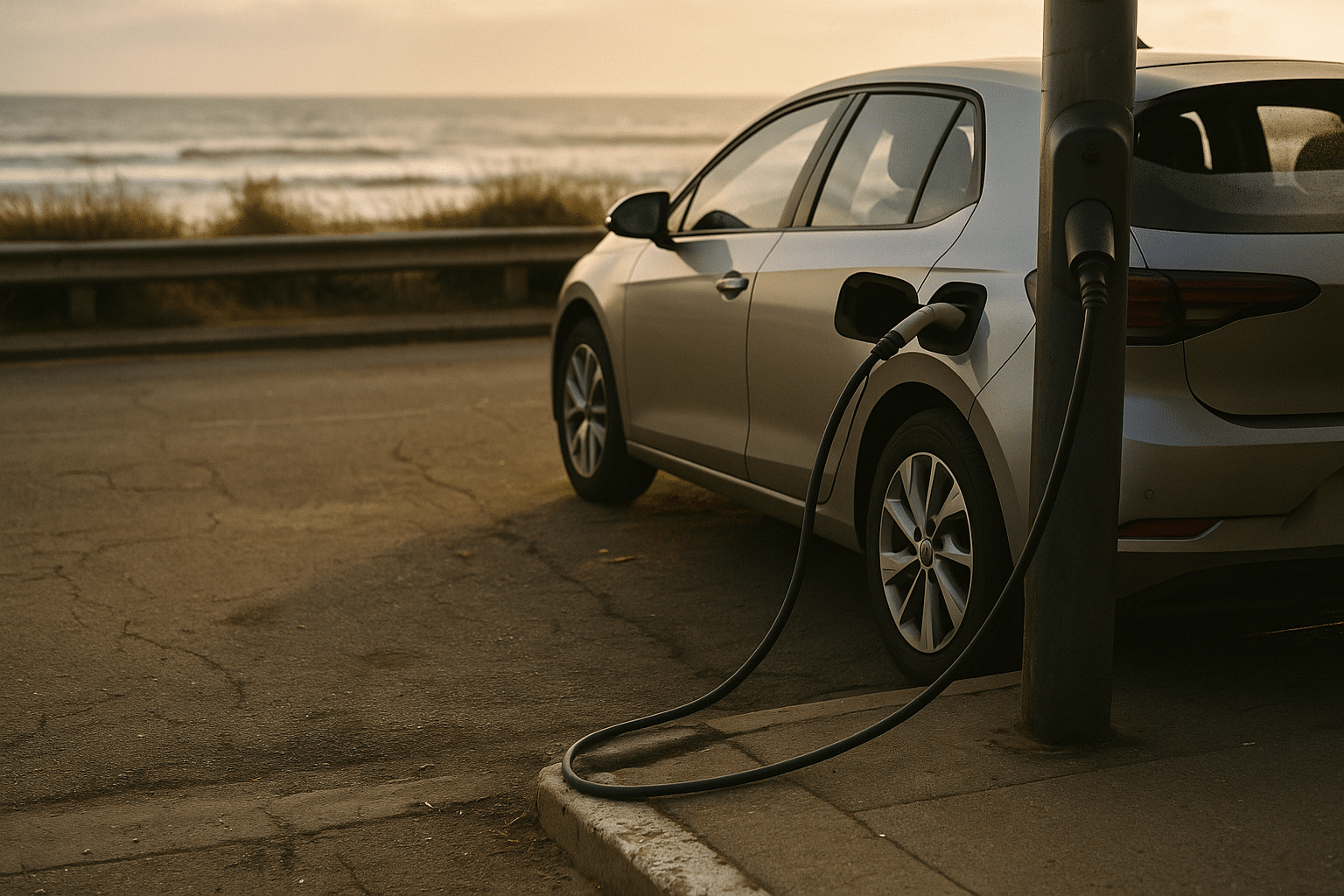

Charging, Infrastructure, and the Grid: From Driveway to Highway

Charging is where vehicle convenience meets energy infrastructure. At home, typical alternating‑current charging delivers about 1.4–3.6 kW from a standard outlet or 7–11 kW from a dedicated circuit, adding roughly 20–60 kilometers of range per hour depending on vehicle efficiency. For many drivers, this quietly refuels the car overnight, turning every morning into a “full tank” routine. Workplace charging can fill the same role for apartment dwellers. Public fast charging, by contrast, provides direct current at 50–350 kW, enabling 150–300 kilometers in 15–30 minutes under favorable conditions. Cold weather, high states of charge, or large packs can stretch those times.

Real‑world experience hinges on reliability. A robust network targets uptime of 97% or higher, short queues, clear signage, and functional payment. Behind the scenes, battery preconditioning, compatible connectors, and well‑designed cable lengths smooth the experience. Charging curves vary: many vehicles ramp quickly to a peak, hold near that power for a short window, then taper as the battery fills. Planning around that plateau—arriving warm, starting under 40% state of charge, leaving around 80%—often minimizes road‑trip dwell time.

Costs differ by venue. Home rates can fall near 0.10–0.20 USD/kWh on off‑peak plans, translating to roughly 2–5 USD per 100 kilometers for an efficient compact. Urban public fast charging typically ranges higher, and highway sites can command a premium in the 0.35–0.60 USD/kWh band. Compare that to combustion energy costs, which fluctuate with global fuel markets and local taxes. Drivers who blend home charging for daily needs with occasional highway fast charging often achieve a favorable overall energy spend.

The grid story is evolving from concern to capability. Managed charging shifts demand away from peak hours, flattening loads and making better use of existing infrastructure. Bidirectional systems, already appearing in select models and chargers, allow vehicles to power homes during outages or export to the grid during constrained periods. Even modest participation—say, a 60 kWh pack providing 5–10 kW of backup—can keep essentials running or reduce a household’s peak draw. Aggregated across neighborhoods and fleets, this flexibility becomes a virtual power plant that complements renewable generation and reduces the need for peaker plants.

For households, buildings, and fleets, a practical playbook is helpful:

– Start with a site assessment: panel capacity, parking layout, and Wi‑Fi or cellular coverage

– Use load management to share circuits across multiple ports and control peak demand charges

– Favor locations with lighting, shelter, and amenities to make charging time productive

– Keep cables and connectors clean, and report faults promptly to improve reliability for everyone

Software-Defined Vehicles, Automation, and Connected Services

Today’s electric vehicle is as much a computer on wheels as it is a machine of metals and motors. Energy use is orchestrated by software that coordinates traction inverters, heat pumps, battery thermal loops, and predictive navigation. Route planning factors in elevation changes, temperature, traffic, and wind; a good planner estimates arrival state of charge within a few percentage points and recommends efficient charging stops. Over‑the‑air updates refine range estimates, add features, and address security issues without a service visit. The result is a vehicle that improves throughout ownership, much like a smartphone—only with safety‑critical rigor.

Driver assistance is evolving, but it is not autonomy in the grand sense. Lane centering, adaptive cruise, and automated parking can reduce fatigue, especially in stop‑and‑go traffic. However, drivers remain responsible and must stay attentive. Higher levels of automation are under development and may appear first in controlled domains—low‑speed shuttles, well‑mapped corridors, or depot‑to‑depot freight. Even modest features can enhance safety when used correctly, and real‑world studies increasingly link such systems to reduced collision rates; the key is clear human‑machine interfaces and conservative defaults.

Connectivity brings benefits and obligations. Telematics can turn fleet operations into a data‑driven discipline: monitoring state of charge across dozens of vehicles, predicting battery health, and scheduling charging when rates are lowest. Home integration lets drivers set charge limits, schedule preconditioning on cold mornings, and authorize guest charging. With that power comes responsibility to protect privacy and security. Strong encryption, multifactor authentication, and signed updates are table stakes; regular penetration testing and swift patching are signs of a mature ecosystem. Owners should review data‑sharing settings, keep apps updated, and treat vehicle accounts with the same care as banking credentials.

Software also mediates trade‑offs among comfort, efficiency, and performance. A dynamic heat pump can cut winter energy overhead by several kilowatt‑hours per 100 kilometers compared to resistive heating, but only if algorithms juggle cabin comfort, windshield clarity, and battery temperature. Similarly, eco‑routes that avoid high speeds can save energy but may add time; the right balance depends on the day. These choices are not static—machine‑learning models improve forecasts as fleets accumulate data across climates and terrains.

Practical takeaways:

– Use built‑in energy routing for trips outside your usual range; it’s more accurate than generic map apps

– Enable battery preconditioning before fast‑charge stops in cold weather

– Keep software updated and review permissions in companion apps quarterly

– For fleets, integrate telematics with utility rate schedules to automate off‑peak charging

Conclusion: A Practical Roadmap for Drivers, Fleets, and Cities

The transition to electric mobility rewards preparation. For individual drivers, start with an honest audit of your daily distance, access to charging, and local electricity tariffs. If home charging is possible, a 7–11 kW circuit with smart scheduling covers most needs and keeps costs predictable; if not, a blend of workplace, community, and corridor charging can still work with a bit of planning. Consider total cost of ownership rather than sticker price alone, and test‑drive with an eye toward ride quality, visibility, charging curve transparency, and driver‑assistance behavior.

For fleets, electrification is a math problem with an operational twist. Duty cycle data—trip lengths, payloads, dwell times—identifies low‑hanging fruit that can electrify first. Depot charging with load management reduces demand spikes, and standardized hardware simplifies maintenance. Range buffers matter: aim for typical daily use of 50–70% of real‑world capacity to accommodate weather and detours. Pilot programs help refine assumptions, train drivers, and document savings. Many operators report maintenance reductions and improved driver satisfaction once routes are matched to vehicles thoughtfully.

Cities and utilities play a coordinating role. Curbside and hub charging fill gaps for residents without driveways; transparent pricing and published uptime metrics build trust. Streamlined permits and pre‑approved designs speed installations at workplaces and multi‑unit buildings. Managed charging tariffs and incentives for bidirectional capabilities encourage vehicles to support the grid, not stress it. Planning should include equity from the start: prioritize access in underserved neighborhoods and align public charging with transit, bike networks, and walkable districts to reduce total transport demand.

As you map your path forward, keep three lenses in view:

– Technical lens: match chemistry, charging power, and software features to your climate and use cases

– Economic lens: compare lifetime energy and maintenance with realistic utilization, not brochure values

– Social lens: support responsible sourcing, recycling, and accessible infrastructure in your community

The road ahead is not a straight line, but the destination is coming into focus: quieter streets, cleaner air, and vehicles that cooperate with the energy system rather than working against it. By blending practical planning with measured ambition, drivers, fleets, and cities can capture the advantages of electric mobility while acknowledging its challenges. That combination—curiosity plus discipline—is how future mobility becomes everyday reality.