Solar Panel Roof Installation

Outline:

– Assessing your roof and energy needs

– Permits, incentives, and grid interconnection

– The installation process and safety essentials

– Costs, ROI, and selecting an installer

– Maintenance, monitoring, and conclusion

Why Solar on the Roof Matters: From Sunlight to Reliable Home Energy

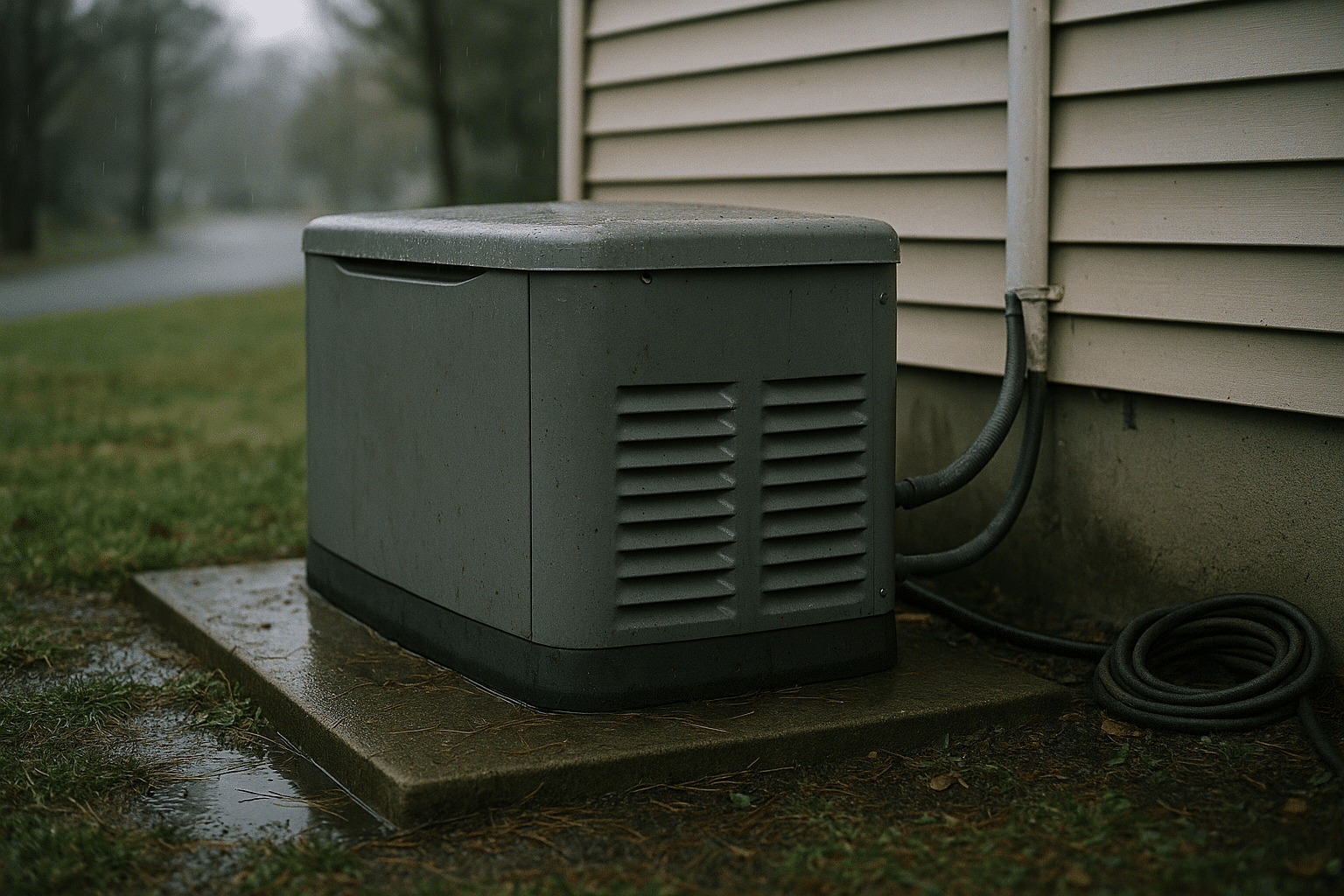

Solar panel roof installation turns idle roof space into a steady source of electricity. For many households, this shift offers three practical benefits: budget predictability, energy resilience, and reduced emissions. Electricity costs can fluctuate year to year, yet a rooftop system allows more control over a portion of your consumption. When grids are constrained by heat waves or storms, a well-designed system paired with storage can soften disruptions. And for residents mindful of environmental impact, distributed clean generation reduces the carbon intensity of your home’s energy mix.

Before diving into hardware, step back and assess your energy profile and roof. An average home may consume 6,000–12,000 kWh annually, though your utility bills provide the real picture. In many temperate regions, a 1 kW array produces roughly 1,000–1,700 kWh per year, depending on latitude, weather, and shading. With those reference points, you can estimate system size: for example, 8,000 kWh/year divided by 1,400 kWh/kW suggests around 5.7 kW. Fine-tuning comes later with a site audit, but early estimates help align expectations.

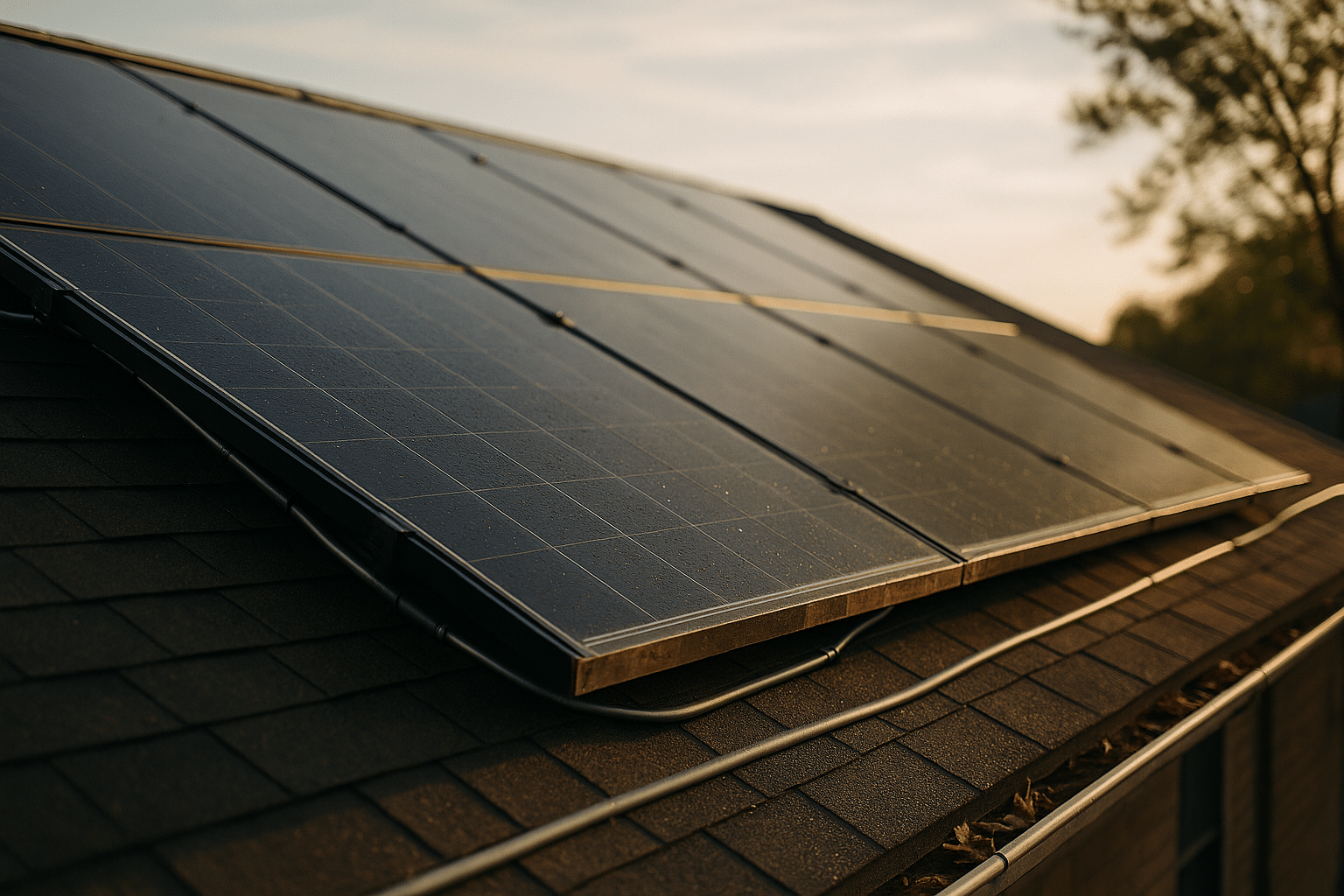

Your roof condition matters as much as sunshine. Most pitched roofs handle the added weight of racking and modules—typically about 2–5 pounds per square foot (roughly 10–25 kg per square meter)—but older structures or those with prior damage warrant a structural review. Orientation and tilt play a major role: in the northern hemisphere, south-facing is generally the strongest performer, with tilt angles near local latitude often producing a balanced annual yield. East- and west-facing layouts still deliver meaningful energy, sometimes with better output in morning or late afternoon hours that align with household use.

A quick checklist can clarify readiness:

– Roof age: ideally, install on a roof with at least 15–20 years of life remaining.

– Shading: chimneys, trees, and nearby buildings can reduce yield; even partial shading affects string performance without module-level electronics.

– Roof material: asphalt shingles, standing seam metal, and many tile systems are compatible with proven attachment methods; flat roofs commonly use ballasted or mechanically attached racks.

– Electrical capacity: a modern service panel simplifies interconnection and future upgrades such as an electric vehicle charger or heat pump.

Approaching your project with these fundamentals establishes a clear path forward. It also signals what to discuss with a professional: roof reinforcement, layout constraints, electrical upgrades, and whether battery storage or load management tools would add value. With a measured plan, you’ll move from curiosity to a system designed for your home’s specific realities.

Permits, Incentives, and Interconnection: Navigating Rules Without the Headaches

Every solar roof project intersects with three layers: building codes, incentives, and the utility. While requirements vary by location, the goals are universal—safety, durability, and accurate accounting of energy flows. Expect a permit package that includes a site plan, structural notes, a roof layout with fire access paths, equipment specifications, and an electrical single-line diagram. Inspectors check that penetrations are flashed correctly, conductors are sized and protected, grounding and bonding are correct, and clearances are maintained around ridges and eaves for firefighter access.

Utility interconnection policies determine how your system exchanges energy with the grid. Some regions offer net metering, which credits exported energy against usage; others apply net billing or time-of-use structures that value solar differently across the day. You’ll submit an interconnection application, await approval, and receive a permission-to-operate after final inspection. If you plan to add a battery, confirm whether your interconnection allows export from storage, requires non-export modes, or mandates specific control settings to ensure grid safety.

Incentives can offset upfront costs, but they require documentation and timely applications. Many areas provide a blend of credits, rebates, or performance-based payments. While amounts vary, homeowners often see incentives that reduce total costs by a notable share when combined—sometimes in the low double-digit to roughly one-quarter range of the project price. Local or regional programs may add fixed-per-watt rebates, low-interest financing, or property tax considerations. Always read eligibility criteria closely; some incentives require using certified equipment, licensed contractors, or specific installation practices.

Keep a practical folder—digital or physical—with these essentials:

– Permit and interconnection forms, stamped drawings, and data sheets.

– Proof of property ownership and, if applicable, homeowners’ association approvals.

– Photos documenting roof condition before and after installation for warranty records.

– Incentive timelines, submission receipts, and award letters or certificates.

A realistic schedule helps set expectations. Design and permitting can take a few weeks to a few months, depending on local volume and utility review times. The physical installation is typically brief by comparison—often one to three days for a standard residential system—followed by inspections and utility approval. By approaching the process methodically, you reduce delays and avoid missing incentive windows that contribute to overall value.

The Installation Process: Step-by-Step Workflows and Smart Safety Practices

Once permits and plans are in hand, installation unfolds through a sequence designed for safety, waterproofing, and electrical integrity. Crews begin with site preparation, establishing fall protection and staging materials. Layout lines are snapped to align rows, and attachment points are located at structural members. Flashing or specialized clamps secure racking to the roof while preserving weatherproofing; on standing seam metal, non-penetrating clamps often anchor rails to the seams themselves.

Racking assembly follows, with rails leveled to avoid module twist and to maintain a uniform plane. Modules are then placed, typically clamped along the frame edges with specified torque to ensure mechanical security and electrical bonding. Attention to wire management pays dividends: cables should be supported, clear of roof surfaces, and protected from abrasion. Junction boxes, home runs, and conduit routes are laid out to minimize penetrations and visually blend with the roof when possible.

Electrical architecture is a pivotal choice. String inverters streamline wall-mounted conversion with centralized monitoring, while module-level electronics provide panel-by-panel optimization and rapid-shutdown functionality. Each approach has trade-offs: centralized inversion simplifies maintenance at a single location, whereas module-level devices can improve production on partially shaded roofs and offer more granular diagnostics. Verify that the system supports required rapid shutdown, grounding, surge protection, and labeling consistent with local electrical code.

Commissioning confirms that design intent matches reality. Installers test open-circuit voltage, short-circuit current, polarity, and insulation resistance. Inverter settings are configured for the local grid profile, and monitoring platforms are activated to track production and alerts. A tidy as-built package—photos, updated diagrams, model numbers, warranty registrations—serves as your long-term reference.

Safety remains the thread stitching everything together:

– Roof work demands fall protection, stable ladders, and clear pathways.

– Electrical testing should be performed with calibrated meters and appropriate personal protective equipment.

– Penetrations must be flashed and sealed according to manufacturer instructions and local standards.

– Walkways around ridges, hips, and skylights preserve access and reduce accidental damage.

When the crew steps back and you see straight rows, neat conductors, and documented test results, you’re looking at more than a neat installation—you’re looking at decades of daily serviceability built into the details.

Costs, Payback, and Choosing an Installer: Turning Quotes into Confident Decisions

Understanding costs starts with the per-watt price, which bundles modules, racking, inverters or optimizers, balance-of-system components, labor, design, permits, and overhead. For many homeowners, quotes often fall within a broad range—commonly around two to four currency units per watt before incentives—shaped by roof complexity, equipment selection, labor rates, and regional market dynamics. Complex roofs, long conductor runs, or service panel upgrades can nudge prices upward, while simple layouts with streamlined permitting can hold costs down.

Value emerges over time. Consider a 6 kW system producing 8,000 kWh annually. If your average electricity rate is modest and rises gradually, the system can offset a meaningful portion of your bill each year. Degradation—often in the 0.3–0.8% per year range—means output declines slowly over decades, which is typically accounted for in long-term projections. Simple payback varies widely with local rates and incentives, sometimes landing within a single-digit number of years in high-rate areas or extending to more than a decade where electricity is inexpensive.

An apples-to-apples comparison requires consistent assumptions. Ask each installer to provide the same usage baseline, production estimate, and shading analysis. Check warranty coverage: many modules include a performance guarantee to a defined percentage of original output by year 25 and a product warranty spanning one to two decades. Inverters often carry different terms than modules. Roof attachment hardware and workmanship warranties are equally important since they safeguard against leaks or installation defects.

When reviewing proposals, look for clarity and evidence:

– Transparent scope: equipment models, counts, layout, and electrical one-line diagram.

– Production modeling inputs: weather datasets, shading factors, and system losses.

– Warranty details: terms, claim process, and responsibilities for labor during replacements.

– Schedule: design, permitting, installation, and utility approval milestones.

– Service plan: monitoring setup, annual checkups, and response times for issues.

Choosing a contractor is as much about communication as credentials. Verify licensing where required, confirm insurance, and ask for recent local projects you can drive by. A contractor who explains trade-offs—panel type vs. layout efficiency, centralized vs. module-level electronics, or the merits of adding storage—equips you to make a confident, goal-aligned decision.

Maintenance, Monitoring, and Long-Term Confidence: Keeping Your Array in Top Shape

Solar roofs are low-maintenance by design, yet a little attention preserves performance and peace of mind. Monitoring is your day-to-day window: production graphs should follow seasonal patterns, rising in bright months and dipping during overcast periods. Sudden drops can signal shade from new tree growth, tripped breakers, or inverter faults. Module-level monitoring, if installed, can pinpoint a single panel affected by debris or shading, while whole-system monitoring offers a broader view of daily and monthly trends.

Cleaning needs are site-specific. In areas with regular rainfall, dust and pollen often wash off naturally. Arid or high-dust regions may benefit from occasional rinsing with soft water and a gentle brush, avoiding harsh chemicals and high-pressure sprays that could compromise seals. Safety first: clean from the ground where possible using extension tools, and schedule roof work when surfaces are dry to reduce slip risk.

Plan simple seasonal checks:

– Visual scan: look for cracked tiles near attachments, loose conduit straps, or dislodged critter guards.

– Wire management: ensure cables remain secured with UV-stable fasteners and above abrasive surfaces.

– Drainage: keep gutters and valleys clear to prevent water back-up near penetrations.

– Landscaping: trim branches that encroach on sun paths or drop debris.

Warranties frame long-term expectations. Many modules carry a performance warranty guaranteeing a defined percentage of original output after 25 years, along with a separate product warranty. Inverters and power electronics have their own timelines; some are extendable. Keep documentation organized—purchase receipts, serial numbers, registrations, and contact details—so claims, if ever needed, are straightforward. At the end of service life, recycling options for modules and metals are expanding, helping divert materials from landfills and recover valuable resources.

Conclusion: For homeowners seeking steadier bills, added resilience, and a practical sustainability upgrade, rooftop solar can be an outstanding fit when planned with care. Start with a candid roof and energy assessment, follow local rules diligently, hire a contractor who explains choices clearly, and commit to light but regular maintenance. With those habits, your roof does more than shelter your home—it quietly powers it, day after day, for decades.